and…what to do about it…

As coal fired utilities continue to cycle, the constant startups and shut-downs wreak havoc on real-time PS 12A compliant monitors originally designed to sample continuously on base loaded units. Starting up with fuel oils which create soot, pausing for weeks at a time, intermittent use of halogens and activated carbons is a difficult obstacle course for many real-time (PS 12A) mercury monitors to maneuver through while still remaining accurate… let alone reliable. They require lots of highly-skilled technician time for maintenance in order to pass the daily, weekly, and quarterly system integrity checks.

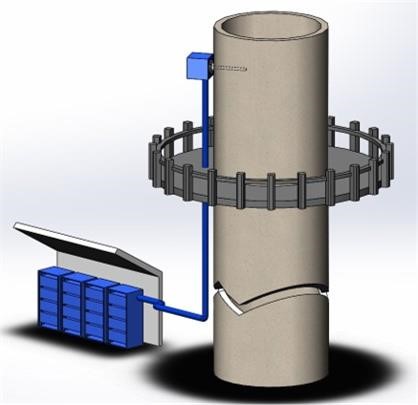

For these reasons, more and more plants have turned to mercury sorbent traps for compliance monitoring (PS 12B) due to the flexibility traps offer plants. Sorbent trap systems are inexpensive, reliable, simple to maintain, and easy to use while operations remain up and down. For sorbent traps, unit cycling is no problem as traps are started and stopped with unit operations. In addition, traps are changed out regularly so soot or halogen accumulation is never an interference.

Sorbent traps also capture Hg over a period of time which allow plants to report with average concentrations rather than publicly divulge the peaks and valleys of plant emissions data which can be dramatic depending on conditions during a start-up or with fuel changes. Over and over, sorbent traps have proven themselves to be reliable, user friendly, and cost effective. But they still possess one major downside. They are not real-time and depending on the lab where they are analyzed, it can take days or even weeks to receive results. This certainly does not leave a plant operator with the warm and fuzzy feeling of knowing they are “in compliance.”

For this reason, some plants have turned to sorbent trap changeouts more times per week. Though this is great for our business, it hurts our heart as we strive to make sorbent traps the optimal choice for the industries we serve.

But did you know there is another option?

All the benefits of sorbent traps for compliance monitoring WITH mercury concentration data in real-time! The ability to change out your traps once a week without fear of being out of compliance!

Thank you 915J REAL-TIME Hg Process CEM!

A mercury process monitor paired with sorbent traps for compliance gives a plant the best opportunity at success from a mercury monitoring standpoint. A process monitor allows you to see in real-time what your sorbent traps see over the period of a week. This is beneficial because real-time feedback will allow you to notice any spikes in emission levels and fix the issues before it is too late. Moreover, if the plant utilizes any control technologies, the real time feedback from a process monitor will allow the operator to control the injection rate to ensure compliance while avoiding over-injection and thus realizing significant cost savings. The 915J has been specifically tailored to fit this function. It is extremely sensitive at low levels and measures mercury without any potential interference by utilizing Zeeman background correction technology. Alternative real-time compliance CEMs on the market are designed according to compliance method PS 12A and thus have certain limitations which lead to high maintenance and deficient sensitivity/resolution, among other issues. The simplicity and reliability of sorbent traps for compliance, paired with the sensitivity and low maintenance of the 915J Process Monitor offer the BEST chance for successful mercury monitoring.

I know…You must be saying it’s crazy to maintain 2 systems!

But, in reality, this dual approach is more reliable, more cost effective and less maintenance than using a PS 12A compliant mercury CEM.

Let us prove it to you! Please contact Alexandra for quote and/or a detailed presentation.