Back in the spring, we mentioned one of the projects we’d been working on was designing a sorbent trap for continuous measurement of metal Hazardous Air Pollutants (HAP). We published a few other articles about it as well, such as:

- EGU NESHAP allows for use of HAP Metal Continuous Monitoring Systems (CMS) as an Alternative to PM CEMS!

- HAP Metal CMS language in the recent MATS update

Since it’s been a few months since our last update, we figured it was high time to share a progress update with everyone. After extensive testing and feedback from our users, we’ve made several significant changes aimed at optimizing performance and reliability. Here’s a summary of the key updates:

1. Reduced Background Metals

One of the most notable improvements is the reduction of background metals in the sorbent. We’ve achieved a 90% reduction since our last update, bringing the total background concentration down to approximately 4% of what it was at the start of Phase II. We are actively working to lower this even further with each new batch of material we produce.

2. Redesigned Filter

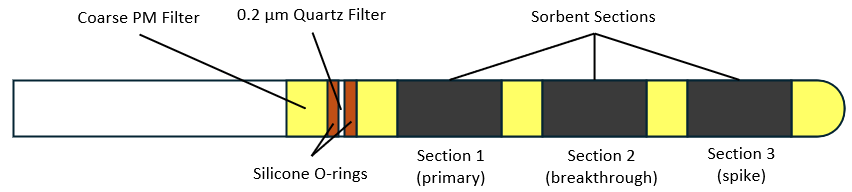

We’ve addressed an issue where separation between the filter and section 1 was occurring due to a high pressure differential across the quartz filter. This separation led to inconsistencies in measurement. Our redesigned filter, which adds an o-ring on both sides of the filter (see below), now prevents this issue, ensuring more accurate and reliable data.

3. Improved Spike Recoveries

Initially, our spike recoveries averaged below 75%, primarily due to a digestion problem. We’ve revised our digestion procedure, and now are achieving close to 100% recovery, with only occasional outliers. This improvement enhances the overall accuracy of our results.

4. New Conical Silicone Insert

To tackle the loss of particulate matter in traps exposed to extremely high PM concentrations, we’re planning to replace the PVC cap with a conical silicone insert. This design allows for the effective retrieval of any PM that slides forward in the trap. We are also advising users to keep the probe level or slightly tilted upwards after removal to mitigate losses.

5. Full-Length Heater Recommendation

We’ve observed four instances of contamination in section 3 due to water running down the probe liner in probes lacking full-length heaters. To combat this, we recommend the use of full-length heaters and again stress the importance of keeping the probe level during and after removal.

Future Plans

Our commitment to improving the HAP metals sorbent trap continues. In the upcoming year, we plan to:

- Further Reduce Filter Background: We’re currently working on minimizing the background on our filter, which, while small for extended runs, is significant for shorter 2-hour tests. The most recent tests have yielded a 70% reduction in chromium and 45% reduction in nickel in the filters – which we plan to improve further.

- Method 29 Comparisons: We will conduct thorough comparisons with Method 29. We have two projects comparing the methods this winter, and plan to collect additional comparison data next year.

- Draft Performance Specification: Based on the data we’ve gathered, we will be drafting a performance specification that accurately reflects our traps’ capabilities. We will begin working with EPA on the performance specification within the next two months.

Conclusion

These updates represent our ongoing commitment to providing the most effective and reliable HAP metals sorbent traps on the market. We appreciate the feedback from our users, which has been invaluable in guiding these improvements. As we continue our method development, we look forward to sharing more advancements in the future.

For more information or to discuss how these changes can benefit your operations, please reach out to Alexandra.