Method Summary

Ohio Lumex is currently developing a sorbent trap method for continuous monitoring of metal Hazardous Air Pollutants (HAP) emissions, with support from the U.S. Environmental Protection Agency (EPA) Small Business Innovation and Research (SBIR) program. The information provided here summarizes the method’s characteristics and status as of May 14th, 2024.

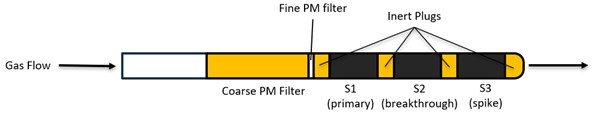

The sorbent trap method is modeled after EPA Performance Specification 12B (PS 12B) for mercury, extended to cover a range of other metals, including, but not necessarily limited to: Sb, As, Be, Cd, Cr, Co, Cu, Pb, Mn, Ni, Se, and Zn. The sorbent traps are specially designed and produced by Ohio Lumex to capture filterable metals (bound to particulate matter) and vapor-phase metals. This is accomplished with the use of a two-stage filter inside the trap, followed by two sections of sorbent material. A third section of sorbent material is added if a spiked section is required for the application. See Figure 1 below.

Metal HAP emissions from stationary sources are currently estimated using emissions factors derived from intermittent stack testing measurements, input feed stream data, and plant operating parameters. Emissions factors may have significant uncertainty, particularly for sources where feed stream metal content is highly variable. Continuous measurements are needed to provide superior accuracy, but current technology is limited and cost prohibitive.

The sorbent trap method would meet that need with repetitive in-stack sampling, using paired sorbent traps with periodic analysis of time-integrated samples collected over a period of several days. This innovative and performance-based method will include robust quality controls, including pair agreement, breakthrough measurements, and spike recoveries (optional).

This method will also provide a superior alternative to EPA Method 29, an impinger-based sampling method which is generally regarded as cumbersome, expensive, and hazardous. Method 29 is also limited to sampling for only a few hours, while the sorbent trap method is designed to be sampled for up to several days at a time, if required.

The sorbent trap method is designed primarily for hazardous waste combustors, metal smelting operations, iron and steel production, secondary smelting facilities, coal-fired power plants, and biogas/renewable natural gas applications.

The sorbent traps are designed to meet the measurement requirements of the recently amended NESHAP for EGUs, which includes reduced concentration limits for total non-HG HAP metals as well as individual HAP metals. The amendments to the NESHAP include specific provisions for utilizing a multi-metal continuous monitoring system, which includes the HAP metals sorbent trap method as an alternative to continuous monitoring of filterable PM.

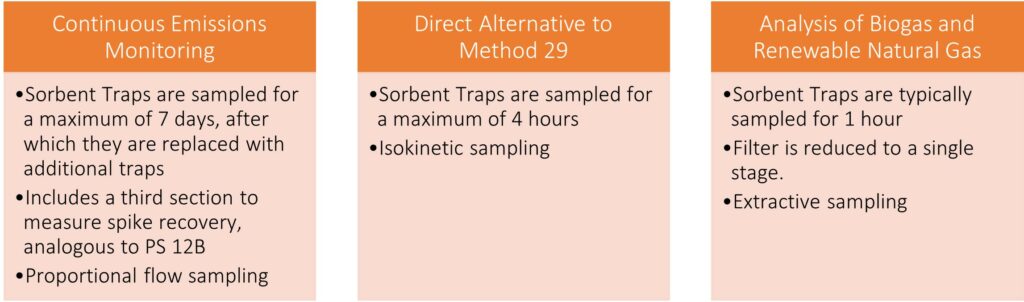

There are three primary applications for the sorbent trap method, and each application has slightly different sorbent trap configurations and sampling characteristics:

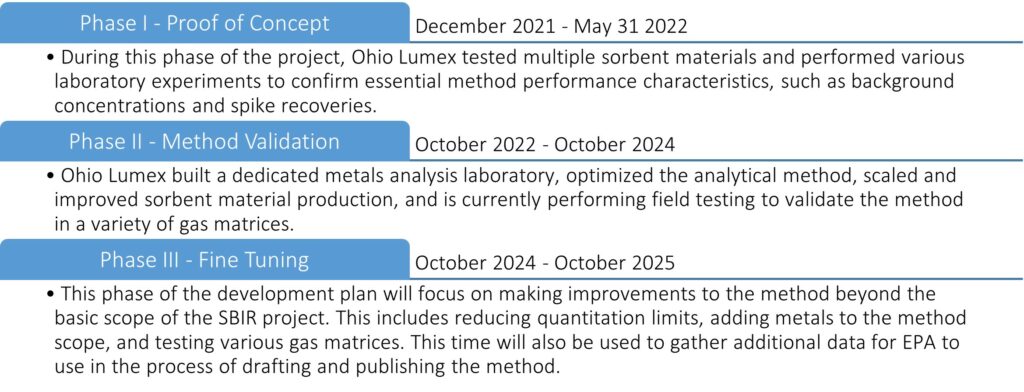

Method Development Schedule

The project was separated into three phases:

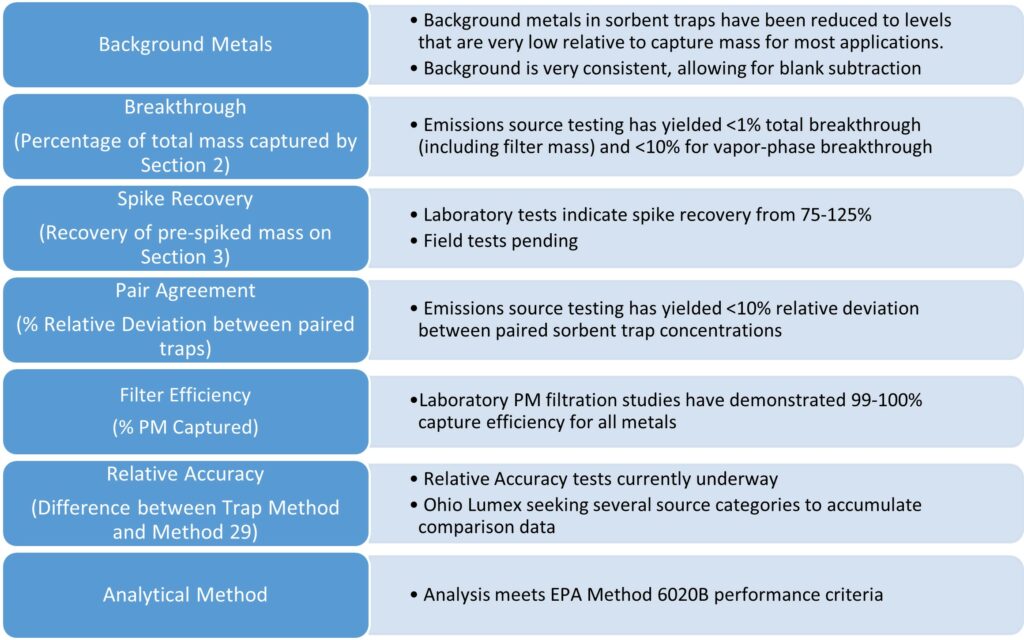

Method Performance and Development Status

As of May 10th 2024, the method’s performance and development status are as follows:

Major Takeaways

Over the last two years, Ohio Lumex has steadily made progress towards the development of a HAP metals sorbent trap. Method Development is nearing completion and recent field tests have demonstrated excellent performance. For some applications, the sorbent traps are ready for use in their current state, while for others additional data is required to validate the method.

Ohio Lumex has several field tests planned for the remainder of 2024, many including the parallel use of Method 29 in order to compare the methods and provide EPA with the data it needs.

For more information, contact Jonathan Cross.