April 2, 2025

Ohio Lumex

Method Status

Ohio Lumex has made substantial progress over the past three years in developing an advanced sorbent trap method for quantifying metal hazardous air pollutants (HAPs) from point source emissions. While the sorbent trap’s ability to effectively capture metals was demonstrated over a year ago, ongoing refinements to trap design, sampling procedures, sample digestion, and analytical techniques have enhanced the method’s accuracy, precision, sensitivity, and overall reliability. While further refinements are planned, the method is already performing at a high level. Ohio Lumex is now leading the next phase of development, drafting two new methods for EPA review: an alternative to Method 29 and a method for continuous metals monitoring.

Method Improvements

Over the past year, approximately 250 sorbent traps have been sampled across 25 test sites. This progress was made possible through strong collaboration with industry partners, particularly coal-fired utilities, who supported field trials of this emerging technology. The resulting data has been instrumental in driving multiple key improvements to the sorbent trap method. A summary of these enhancements is provided below:

Filter Design

Following extensive field sampling in the summer of 2024, a recurring issue was identified where the 0.2 µm quartz filters positioned ahead of section 1 compressed the underlying plugs under high vacuum conditions, causing a gap to form between the filter and the silicone o-ring. This occasionally affected filtration efficiency and contributed to reduced pair agreement. To resolve this, the trap design was updated to include a silicone o-ring on both sides of the filter, securing it in place and preventing plug compression.

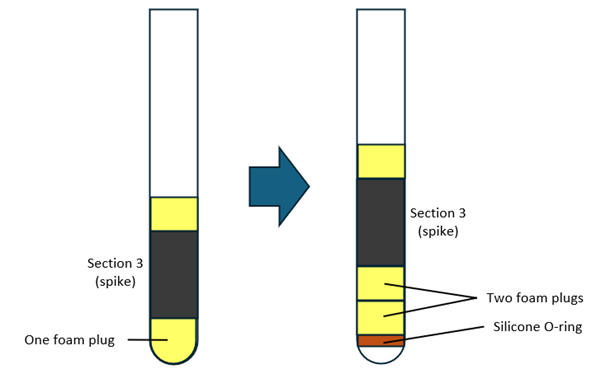

Rear Plug Design

The original sorbent trap design utilized a single high-temperature foam plug at the rear. In two instances over the past year, section 3 was pulled out of the trap and into the sampling probe due to a combination of high vacuum conditions and undersized foam plugs, allowing them to pass through the trap’s tapered end. Although this failure occurred in less than 1% of samples, the design was modified to include a silicone o-ring at the back end, preventing the plug from being pulled out.

Additionally, a second plug was added at the rear of the trap to increase the distance between section 3 and the trap’s exit. This adjustment was made after several section 3 samples were contaminated by water entering the traps from the interior of the probe liner. While this issue can typically be mitigated by using a probe equipped with a full-length heater, it was recognized that not all users may have access to such equipment. The added plug is intended to reduce the risk of water-related contamination; however, it is not a complete safeguard. Significant moisture inside the probe can still compromise the sample. Ohio Lumex recommends using probes with full-length heaters and maintaining the probe in a level or upward-tilted position when removing traps from stack gas environments.

PREVIOUS DESIGN CURRENT DESIGN

Cap Design

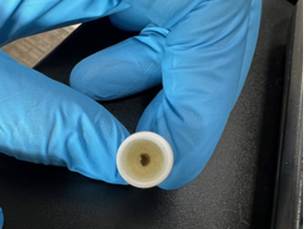

The sorbent trap is designed to capture filterable particulate matter on a 0.2 µm quartz filter, similar to Method 29. However, in cases where significant particulate matter is present, the material may remain loose inside the trap. If the trap is removed without properly securing this material, results may be biased low, as the particulate matter often contains the majority of collected metals.

When using a standard PVC cap to seal the trap, some particulate matter can transfer to the inside of the cap, as shown below. Although particulate matter can be recovered from the cap via acid wash, this process introduces the risk of contamination by leaching metals from dyes in the PVC material itself.

To mitigate this risk, the front PVC cap was replaced with a silicone insert. In addition to eliminating contamination from cap materials, the silicone insert helps secure the filter and plugs, reducing the likelihood of movement or displacement after vacuum release during leak checks.

This image reflects the current design of the 3-section sorbent trap as of March 2025. Further design modifications may be implemented as additional data is collected and new opportunities for improvement are identified.

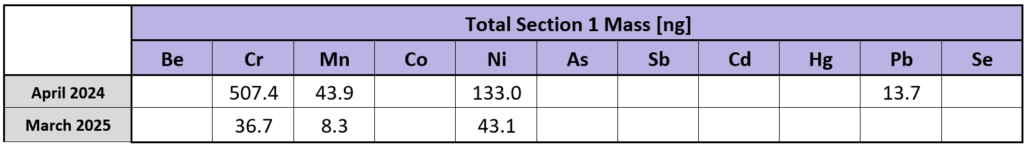

Background Metals

Over the past year, the sorbent material production process has undergone several key refinements, resulting in a significant reduction of background metal concentrations. These advancements have improved the reliability of blank subtraction and enhanced overall data quality.

Ohio Lumex continues to pursue further reductions in background metals, aiming to increase method sensitivity and minimize required sampling durations.

Sampling Method

While the majority of sampling has been conducted using a non-isokinetic method, recent field tests have shown that isokinetic sampling yields more accurate results and better pair agreement. Although non-isokinetic and isokinetic measurements occasionally align, such occurrences are infrequent. Based on these findings, Ohio Lumex recommends that all sorbent trap sampling be performed using an isokinetic sampling system to ensure the most reliable data.

Ohio Lumex is also actively investigating the differences between isokinetic and sub-isokinetic sampling methods using nozzles. This research aims to determine whether the most critical sampling parameter is velocity or direction, which could refine the accuracy and consistency of the sampling process without overcomplicating the sampling procedure.

Dissolved Metals

Several sorbent traps have been received from coal-fired power plants with wet stacks where significant entrained water droplets were present in the stack gas. These water droplets vaporized upon entering the sorbent traps, which are heated to 150°C, leaving behind a residue on the glass interior. This residue contained a notable concentration of several metals, particularly manganese.

We found that a 2% HNO₃ solution was insufficient to remove these deposited metals, requiring a stronger solution. In some cases, it was necessary to cut the glass and soak it in concentrated HNO₃ to fully dissolve the metals.

This discovery has implications for Method 29, which uses a relatively low concentration of ~0.45% HNO₃ to rinse the probe liner. In cases where metals are deposited on the glass probe liner, a stronger acid may be necessary to effectively remove the residues and ensure accurate measurement.

Impact on Performance

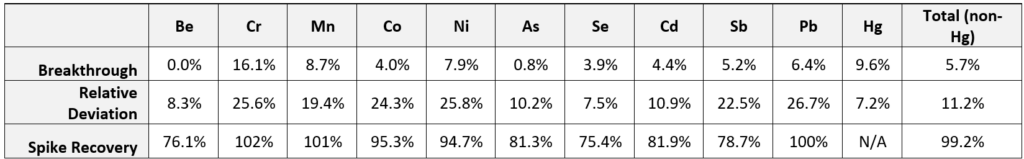

As a result of the various enhancements to the sorbent trap design, reductions in background metals, updates to the sampling method, and refinements in laboratory sample digestion and analysis, method performance has improved significantly.

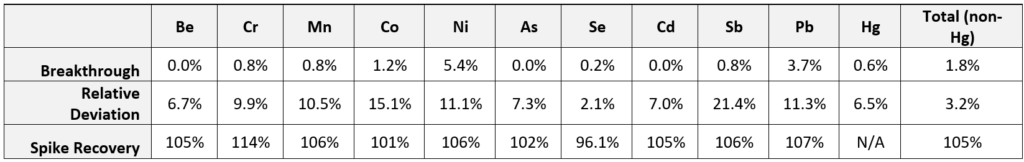

Method performance is evaluated using three key metrics: breakthrough, relative deviation (pair agreement), and spike recovery. The tables below provide a summary of the average performance for all sorbent traps sampled over the past year, divided into two intervals. The second interval, from November 2024 to March 2025, reflects performance after most of the improvements detailed above were integrated into the method.

May 2024 – November 2024

November 2024 – March 2025

Planned Improvements

On average, the performance of the sorbent trap method is excellent and meets the development objectives set out at the start of the project. However, Ohio Lumex continues to identify areas for further improvement. These areas are outlined below.

Background Metals

Since the project’s inception over three years ago, background metal concentrations have been reduced by more than 95%. Despite this significant progress, each improvement offers the potential to further reduce the minimum sampling duration. Currently, it is recommended to sample for at least three hours, unless prior data from the source suggests a shorter duration is acceptable.

Mercury

Several interested parties have inquired about the inclusion of mercury in the sorbent trap method. While the trap shows strong performance in terms of breakthrough and relative deviation, Ohio Lumex has yet to test mercury spiking or assess measurement accuracy when sampling from a source with a known mercury concentration. Testing for mercury is scheduled to begin in late March 2025.

Comparisons with Method 29

In December 2024 and January 2025, under the management of EPRI and in collaboration with a third-party stack tester, Ohio Lumex conducted two field evaluations of the sorbent traps.

Both evaluations followed identical designs, but the December project was carried out at a coal plant with a dry stack, while the January project took place at a coal plant with a wet stack.

Each project spanned three days, during which three runs of Method 29 and three runs of the sorbent trap method were sampled simultaneously each day. Due to limited port size, the probes could not be co-located, and were positioned approximately 20 feet apart.

Method 29 samples were analyzed by a third-party laboratory, while the sorbent trap samples were analyzed by Ohio Lumex.

The full datasets will be available to project sponsors once the EPRI reports are completed. A summary of the data is provided below.

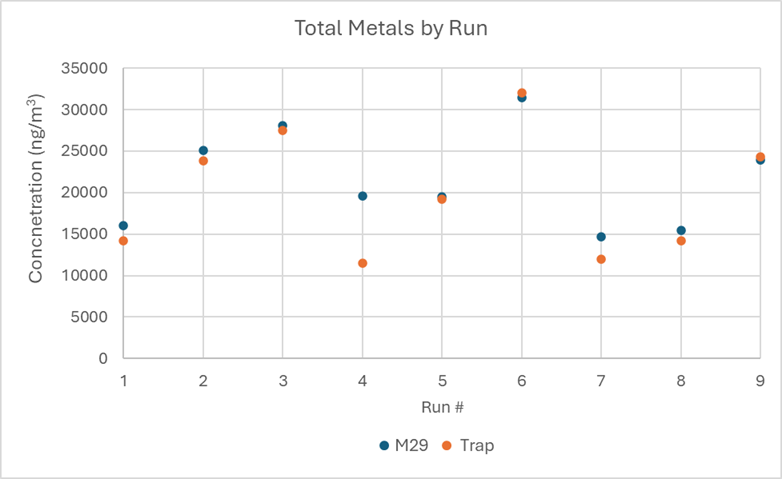

Method 29 Comparison – Dry Stack

The total bias for the dry stack evaluation was calculated to be 7.8%, with the sorbent traps averaging slightly lower than Method 29. Run 4 was identified as a significant outlier, primarily due to exceptionally high concentrations of nickel and chromium measured in the Method 29 sample. Excluding this run brings the total bias down to 4.0%.

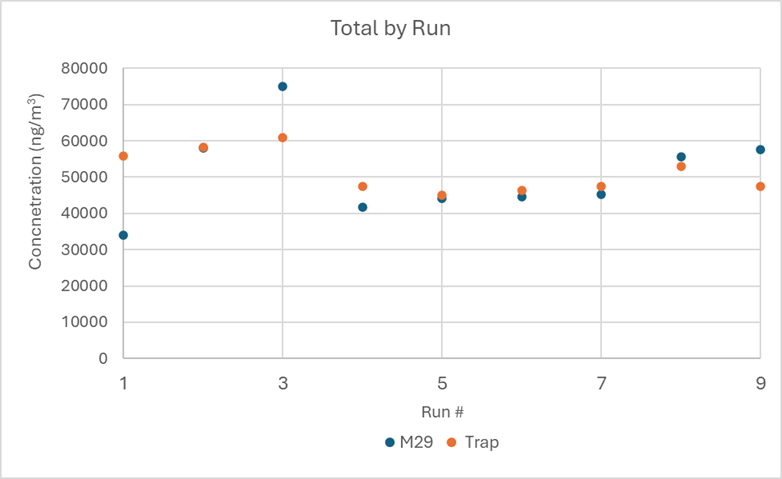

Method 29 Comparison – Wet Stack

The wet stack evaluation presented more challenges, as several Method 29 samples exhibited significant concentrations of multiple metals in the last impinger. These last impinger samples were analyzed separately to check for breakthrough, but they also revealed potential contamination. Runs 1-4 and Run 9 were clearly contaminated, and the Method 29 reagent blanks showed extremely high concentrations of metals such as chromium (Cr), manganese (Mn), cobalt (Co), nickel (Ni), arsenic (As), and lead (Pb). Notably, the blank value for chromium was approximately 50% of the total catch for each sample, and the blank value for lead was about 75% of the total catch.

Fortunately, selenium was the predominant component in the gas, accounting for approximately 90% of the total concentration. Given the strong agreement between the two methods for determining selenium, the total bias for the wet stack was calculated at 1.3% when all runs were included, or 1.2% when the five contaminated runs were excluded.

Advantages of the Sorbent Trap Method over Method 29

The sorbent trap method offers several advantages over Method 29, making it a reliable alternative for measuring hazardous air pollutants:

- Improved Data Quality: The sorbent trap method includes self-validating criteria, such as pair agreement, breakthrough, and spike recovery (similar to EPA Method 30B or PS 12B), ensuring more reliable and consistent data quality than Method 29.

- Reduced Contamination Risks: Method 29 is commonly used for sampling from sources with higher metal concentrations, where it performs well. However, in coal power plant stacks, which typically have lower metal concentrations, Method 29 data can be problematic due to frequent contamination and high reagent blanks relative to the metals captured. The sorbent trap method, on the other hand, is less susceptible to these issues, providing more reliable results in coal stack gas sampling.

- Simplified Sampling Process: Method 29 requires 2-3 stack testers and a clean location to recover samples, making it more labor-intensive. In contrast, the sorbent trap method requires only one person for sampling, and the traps need minimal processing after sampling, streamlining the overall process.

- Cost-Effective: Over time, the sorbent trap method is expected to be more cost-effective than Method 29, particularly as laboratory operations become more efficient and refined.

Draft Methods and Timeline

Two test methods are currently being developed in parallel:

- Alternative to Method 29. This method involves a two-section sorbent trap with an optional spike on section 1, similar to EPA Method 30B but with the addition of a filter before the first section. Ohio Lumex is nearing completion of the draft method, which is expected to be finalized by early April. Once completed, the draft method, along with a Method 301 test plan, will be submitted to the EPA for review. Following EPA approval, a Method 301 validation test can be performed at any eligible plant. Due to the challenges associated with Method 29—particularly contamination, high reagent blanks, and the inability to co-locate probes—Ohio Lumex will pursue the Method 301 “Analyte Spiking” option. This involves conducting quad-train sorbent trap sampling, effectively performing a field recovery test. While passing this test may be challenging due to the natural variability of metals concentrations in stack gas, it offers a higher likelihood of success than directly comparing the sorbent trap method with Method 29.

- A sorbent trap method to be used for continuous monitoring. This method is a three-section sorbent trap, similar to EPA Performance Specification 12B, and would be used for continuous monitoring of metals, such as for compliance with the MATS regulation or future requirements. This method is very similar to the alternative test method, and the first draft is expected to be completed by the end of April.

Both methods are currently under development and must undergo EPA review and approval. Ohio Lumex’s goal is to have both methods published by the end of 2025. More information about the HAP Metals Sorbent Trap and what it measures can be found here. Please contact us with any questions.