AND, how Ammonia Slip can affect Mercury Control…

During the calcination process, cement kilns maintain high levels of combustion generating Nitrous Oxide (NO) and Nitrous Dioxide (NO2), which are generally termed together as NOx. To control these byproducts, Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR) have emerged as key post-combustion solutions to significantly reduce NOx emissions, thus promoting cleaner production in the cement industry. The choice between SCR and SNCR technology depends on the ammonia emission limits and the NH3 in the raw material feed (the baseline). Wherever the baseline is high and the ammonia limit value is low, SCR technology is the best choice for NOx abatement as the SNCR technology adds ammonia to the process gas stream. However, the cost for SNCR technology is substantially lower and so SNCR has gained quite a bit of traction in the cement industry.

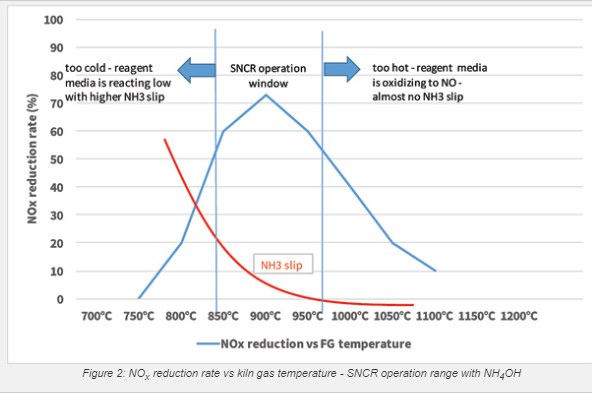

Similar to SCR, the SNCR process involves injecting a reagent, typically ammonia or urea (18-20%) in a water solution into the high temperature zone of the flue gas stream between 1550℉-2000℉ (850°C – 1100°C). Though no catalyst is involved in the reaction, the reagents themselves further oxidize the nitrogen oxide by causing chemical reactions, which leave harmless nitrogen and water vapor as byproducts that are then discharged as exhaust (via the flue) back into the environment. (source)

SNCR has been demonstrated to reduce NOx emission by up to 70%. However, to ensure proper SNCR efficiency, a cement plant’s combustion efficiency needs to be regularly monitored to maintain optimum temperatures between 1550℉-2000℉, otherwise the ammonia / urea will not react properly and ammonia slip will occur. (source) In this case, over-injection of ammonia becomes necessary.

Ammonia slip measurements have traditionally been used to optimize ammonia injection to save money and reduce fouling of downstream equipment, but lowering ammonia slip can also contribute to reducing mercury emissions. The combination of nitrogen oxide and ammonia in the gas stream promotes the reduction of oxidized mercury to its elemental form. (source) This is important because the options to control oxidized mercury are different than those used to control elemental mercury. Understanding what species of mercury are present is important for an effective mercury control strategy. More on this later.

Traditionally, ammonia concentration has been tricky to obtain because the available measurement methods and equipment were cumbersome and expensive. However, with the development of Ammonia Sorbent traps, all that has changed. These are simple to sample with a portable sampling system.

Ammonia Sorbent Traps can be used to easily measure your Ammonia Slip at various operating parameters. Use them to optimize your SNCR, determine deficiencies, prevent over-injection, and track changes over time.

If you are using SCR, there are additional benefits to doing this type of testing that you may want to consider. We wrote about it previously in this article.

The traps are capable of measuring very low concentrations of ammonia with a high degree of accuracy. Generally, a sampling duration of under 30 minutes is sufficient to measure ammonia in the single digit ppm range while higher durations may be needed for ultra-low concentrations. The sorbent trap method is superior to other ammonia measurement methods due to its accuracy, ease of use, and lower cost. To read more about this, see our blog post on Advantages of Measuring Ammonia using Sorbent Traps.

You can also evaluate your mercury species at any point in your plant by using the same sampling system and Hg Speciation Sorbent Traps. They are an excellent tool to see if your Hg control strategy is working well or could be improved.

On a side note, did you know that you can also measure HCl using sorbent traps? It is an official EPA Method EPA OTM-40 and an excellent tool prior to compliance testing or to spot check your HCl CEM or FTIR in case they give you an unexpected reading. To read on about HCl sorbent traps, see this article.